Adaptive Structures Laboratory

Principal Investigator: Dr. Gang Wang

Smart materials and structures are an emerging revolutionary technology requiring multidisciplinary training in the fields of aerospace, mechanical, and materials engineering. The Adaptive Structures Laboratory (ASL) offers a set of unique equipment to conduct both fundamental and applied research when these smart materials are integrated with aerospace structures, such as structural health monitoring (SHM) and energy harvesting. High-efficiency and high-bandwidth power amplifier (AE-Techron 7224) is able to actuate piezoelectric based actuators up to 300kHz. Two NI USB X Series multifunction data acquisition (DAQ) systems are used to generate actuation signals and collect sensor inputs with integrated conditioning capability. Modal shakers are available to conduct dynamic tests to determine free vibration characteristics and dynamic response using ultrafast sampling and accurate laser sensor systems (Keyence LK series) and PCB accelerometer and force transducer. Tektronix digitizing Oscilloscope and Agilent Function Generator are available to conduct wave generation, capture, and analysis in dynamic testing.

Applied Aerodynamics & Flow Control Lab

Principal Investigators: Dr. Haiyang Hu

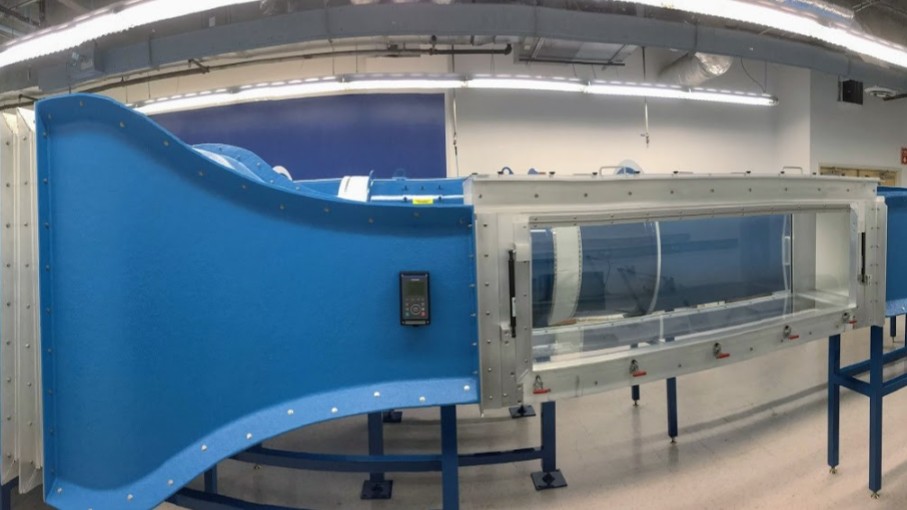

Figure 1: The closed recirculating low-speed wind tunnel

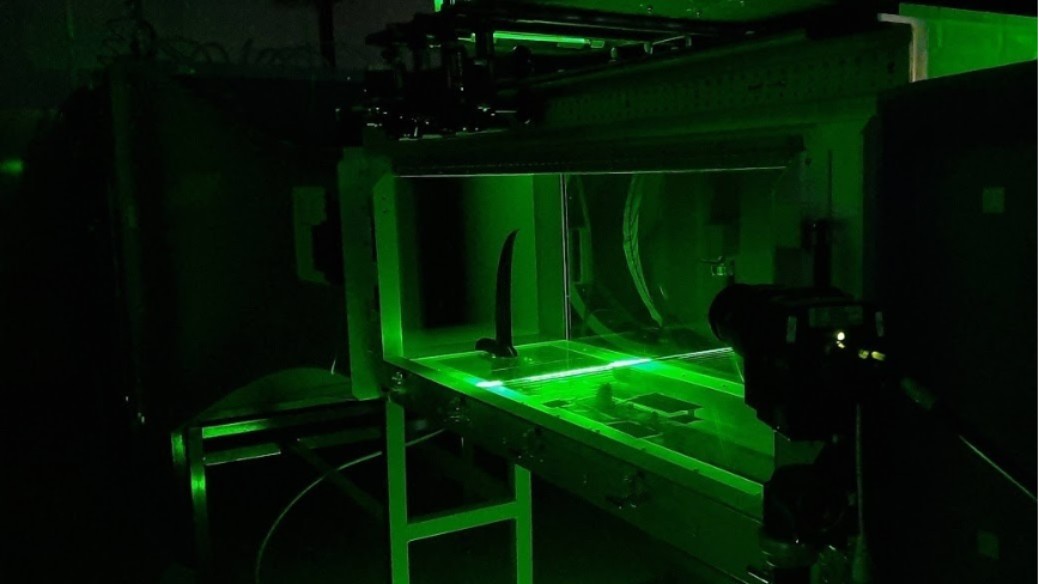

Figure 2: Particle Image Velocimetry test on the near-field of wingtip vortex structure

Autonomous Tracking Optical Measurement Laboratory (ATOM)

Principal Investigators: Dr. Chang-kwon Kang

The ATOM laboratory provides high-speed, low-latency real-time three-dimensional tracking of objects moving freely in a 50' x 30' x 12' unobstructed volume. Thirty-three Vicon T40 infrared cameras can track 50 unique objects at up to 370 frames per second with a latency of 5 milliseconds, and a spatial resolution of 1.5 mm. The ATOM lab allows testing and analysis of systems in disciplines as diverse as robotics, biomimetics, human factors engineering, and virtual engineering. The facility allows freedom to test and analyze whatever can be built.

Charger Advanced Propulsion and Power (CAPP) Lab

Principal Investigator: Dr. Jason Cassibry

Pulsed power and high voltage applications relevant to advanced propulsion and terrestrial power.

Electrochemical Energy Diagnostics & Design (EEDD) Lab

Principal Investigator: Dr. Guangsheng Zhang

EEDD Lab is located in the Engineering Building. This laboratory is for research on in situ diagnostics and novel design of electrochemical energy technologies (e.g. lithium-ion batteries) for electric vehicle, smart electronics, aerospace and renewable energy storage applications. Main facilities include ARBIN 32-channel battery tester, MTI hydraulic driven battery crushing & nail penetration tester, MBRAUN glovebox, Tenney thermal chambers, BRANSON ultrasonic welding machine, MTI vacuum battery sealing machine, LABCONCO fume hood, Thermo Scientific bath circulators, HIOKI battery internal resistance tester, and Keysight data acquisition.

Plasma and Electrodynamic Research Lab (PERL)

Principal Investigator: Dr. Gabe Xu

PERL is located in the Johnson Research Center and conducts experimental research on plasmas, combustion, and propulsion. The lab has three vacuum chambers or different sizes capable of pressures down to 1E-6 Torr to emulate the space environment, various power systems to generate high and low pressure plasmas, a tunable dye laser system, and fast ICCD spectrometer and camera for nanosecond scale measurements. Some projects have included miniature ion and Hall thrusters, plasma purification of water, plasma treatment of seeds and plants, plasma-assisted combustion, laser produced plasmas, magnetized plasmas, and rotating detonation engines.

Transport, Reaction, and Energy Conversion Lab

Principal Investigator: Dr. George Nelson (MAE) and Dr. Yu Lei (ChE)

The Transport, Reaction, and Energy Conversion Lab at UAH is a 1500 ft2 laboratory in the Shelby Center for Science and Technology that houses equipment for materials processing and characterization, electrochemical testing, and catalyst testing. The lab is comprised of the MTEC (Dr. Nelson) and Lei Lab (Dr. Lei). This facility supports research on electrochemical and catalytic material systems relevant to sustainable energy. Materials handling and processing equipment includes: a LABCONCO controlled atmosphere glove box, a fume hood, a 1000 °C box furnace, a 1200 °C Tube Furnace, a vacuum oven, an Elcometer film coater with doctor blade, and an Arradiance GEMStar-6 atomic layer deposition system with ozone generator. Materials characterization equipment includes: a 600 W Rigaku Miniflex X-ray Diffraction (XRD) system, a Woollam Alpha-SE ellipsometer for characterization of powder and thin film materials, and a Quantachrome Autosorb iQ gas sorption analyzer. Electrochemical testing is supported by a Bio-Logic VSP multichannel potentiostat/galvanostat with 5 A boosters and a Bio-Logic SP150 potentiostat/galvanostat with low current measurement capability. Catalyst testing is supported by two gas chromatographs (HP 5890 Series II and SRI 8610) for gas composition analysis and a furnace for environmental control. The VSP potentiostat/galavnostat, XRD system, ellipsometer, and gas sorption analyzer were purchased with support from the UAH Research Infrastructure Fund.

Advanced Propulsion, Energy and Combustion Science Laboratory (APECSLab)

Principal Investigator: Dr. John Bennewitz

Clean Hydrometallurgical Recycling and Environmentally-Sustainable Technologies (CHREST) Laboratory

Principal Investigator: Dr. Natalie Click

The CHREST lab is an interdisciplinary group at the nexus of chemistry and mechanical engineering, focused on propelling sustainable materials and technologies forward. Research topics encompass breadth in polymerization chemistry, electronic waste and battery recycling, photovoltaic cells, and sustainability in space exploration. At its core, all projects in the CHREST group utilize the principles of green chemistry to advance modern technologies in sustainable and circular ways.

Experimental Mechanics and Multiphysics Modeling (E3M) Laboratory

Principal Investigator: Dr. Nathan Spulak

The E3M Lab performs both mechanical testing as well as multiphysics modeling. The lab focuses on determining the coupled mechanical, thermal, and electrical response of materials and devices over a wide range of loading conditions. This includes loading under dynamic conditions and assessing the material strain rate sensitivity, as well as the associated adiabatic temperature rise of materials that occurs during high rate loading. The lab has a split-Hopkinson bar device capable of performing high strain rate testing under compression, tension, and direct shear loading. This is coupled with digital image correlation (DIC) and a high-speed camera with a frame rate up to 1,000,000 frames per second to measure the full-field deformation and strain across the material during the experiments. Full-field temperature measurements can also be obtained using a high-speed infrared camera, with maximum frame rate of 100,000 frames per second. This allows the lab to analyze the coupled mechanical and thermal effects during dynamic loading. The lab also has a servo-hydraulic load frame with both axial and torsional channels and an associated DIC camera system, capable of measuring material response at low and intermediate strain rates under tension, compression, direct shear and torsional loading. Additionally, the lab has a high performance computing server and performs finite element analysis (FEA) simulations, primarily utilizing Ansys LS-DYNA. This coupled experimental and numerical capability allows the E3M Lab to utilize the experimental data to develop more accurate material models and simulation techniques, capable of capturing the coupled mechanical-thermal-electrochemical response of materials as well as of energy storage devices such as batteries. This enables more accurate design and analysis of real-world structures, and advances the fundamental understanding of the mechanisms behind the dynamic behavior of materials.