Ledia Shehu, a doctoral student at The University of Alabama in Huntsville (UAH), has been selected to receive a NASA Future Investigators in NASA Earth and Space Science and Technology (FINESST) grant for her proposal, “Physics-Based Multiscale Constitutive Model for ISRU-Based 3D-Printed Lunar Concrete.” The project seeks to develop a multiscale model for 3D-printed concrete using lunar materials by simulating lunar conditions. The project is set to begin on Dec. 1, 2024, and will run for three years.

“Sending materials to the moon is incredibly expensive,” the UAH researcher explains. “Our solution – using lunar materials to create printable and buildable concrete – will significantly reduce costs and provide a more practical approach to building on the moon. We’re aiming to conduct a detailed theoretical, experimental and numerical study to predict how concrete made from lunar soil and 3D-printed on the moon will behave under different conditions, such as moonquakes, extreme temperatures and more.”

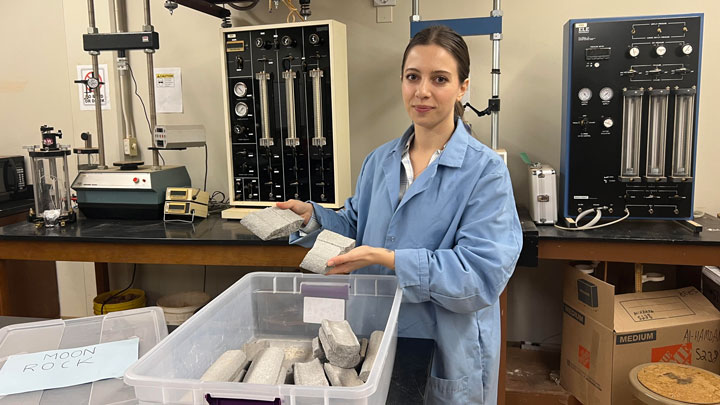

Courtesy Ledia Shehu

The goal of Shehu’s research is to use 3D printing – a process that creates a physical object from a digital model by adding layers of material on top of each other, called “additive construction.” Additive construction (AC) is different from traditional manufacturing, because it adds parts instead of removing material. The process involves digitally controlling the design, production and assembly of a structure and can be more time-efficient than conventional building techniques, while also reducing material waste and improving worker safety.

A “multiscale constitutive model” is a model that describes the mechanical behavior of a material at multiple scales: microscopic, which represents the microstructure of the material, and macroscopic, which represents the collective properties of the material as a whole. Multiscale constitutive models can be used to simulate the mechanical behavior of a variety of materials, as well as simulate factors such as time-dependent deformations like shrinkage and creep.

Originally from Albania, Shehu was drawn to UAH, a part of The University of Alabama System, because of the school’s international reputation at the forefront of aerospace technology and its foundational association with NASA.

“I am a civil engineering student with a concentration in structural engineering and a minor in mechanical and aerospace engineering,” the researcher notes. “I chose UAH because of its strong, long-standing partnership with NASA, which made it the ideal choice for me. I started working as a graduate research assistant with Dr. Yooseob Song [assistant professor of civil and environmental engineering] in fall 2023, as our research interests aligned.”

The project’s aim is to advance the knowledge of the mechanics of in situ resource utilization (ISRU)-based 3D-printed lunar concrete by developing a physics-based multiscale constitutive model and its finite element code.

In this case, 3D printing will be employed to generate a physical substance similar to lunar regolith, the thick layer of unconsolidated rock, pebbles and dust that covers the entire surface of the moon, to experiment with as a potential building material. The research will also employ physics-based theoretical modeling and its numerical simulations as part of the initiative.

“This research will support future lunar construction by making it more efficient and reliable,” Shehu says. “First, we’ll fabricate physical specimens from ISRU lunar regolith-based mixtures using a 3D printer and conduct the necessary testing on these specimens. At the same time, we’ll develop a new constitutive model, as current formulas are not well-suited to 3D-printed concrete or lunar regolith. Finally, we’ll create a corresponding numerical model to simulate the behavior of these materials.”

In addition to financial support, NASA will provide assistance from its engineers and laboratories to advance the research. The funding and collaboration will enable deeper exploration into materials and methods for building on the moon.