Point of Contact: Dr. David Lineberry, email: david.lineberry@uah.edu

The Injector Spray Facility, shown in the image below, provides the ability to cold flow liquid and gaseous rocket injectors (with inert fluids), and rapid prototyped flow components, for the measurement of flow performance, observation of spray patterns, and measurement of droplets. The facility has an atmospheric spray bench dedicated to the observation of sprays at ambient pressures. There is also a high-pressure chamber to observe injection at pressures up to 500 psig and flow rates of up to 2 lb/sec. K-bottle packs or the wind tunnel tank farm supplies the pressure to run the system.

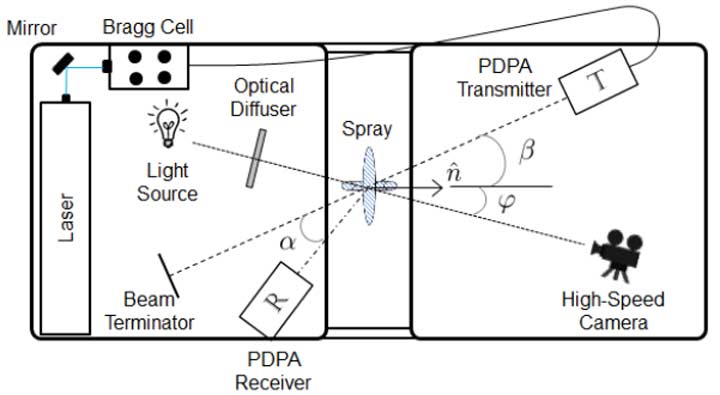

Instrumentation at the facility includes pressure, temperature, and flow rate sensors. There are also high-speed video cameras, a 2-D Phase Doppler Particle Analyzer (PDPA), and a 2-D Particle Image Velocimetry (PIV) system, all for the collection of atomization and velocity profile characteristics in flows and sprays.

2-D Phase Doppler Particle Analyzer.

The PRC Spray Facility

Past work at the facility has included research on impinging and the self-pulsation of swirl coaxial bipropellant injectors. Current work includes developmental testing of shear coaxial injectors, impinging injectors, and fundamental research focused on the effects of surface roughness resulting from additive manufacturing in cavitating venturis.