UAH researchers receive Titomic grant to develop improved cold-spray gun for repairing damaged hardware parts through the spray of high-speed metallic particles

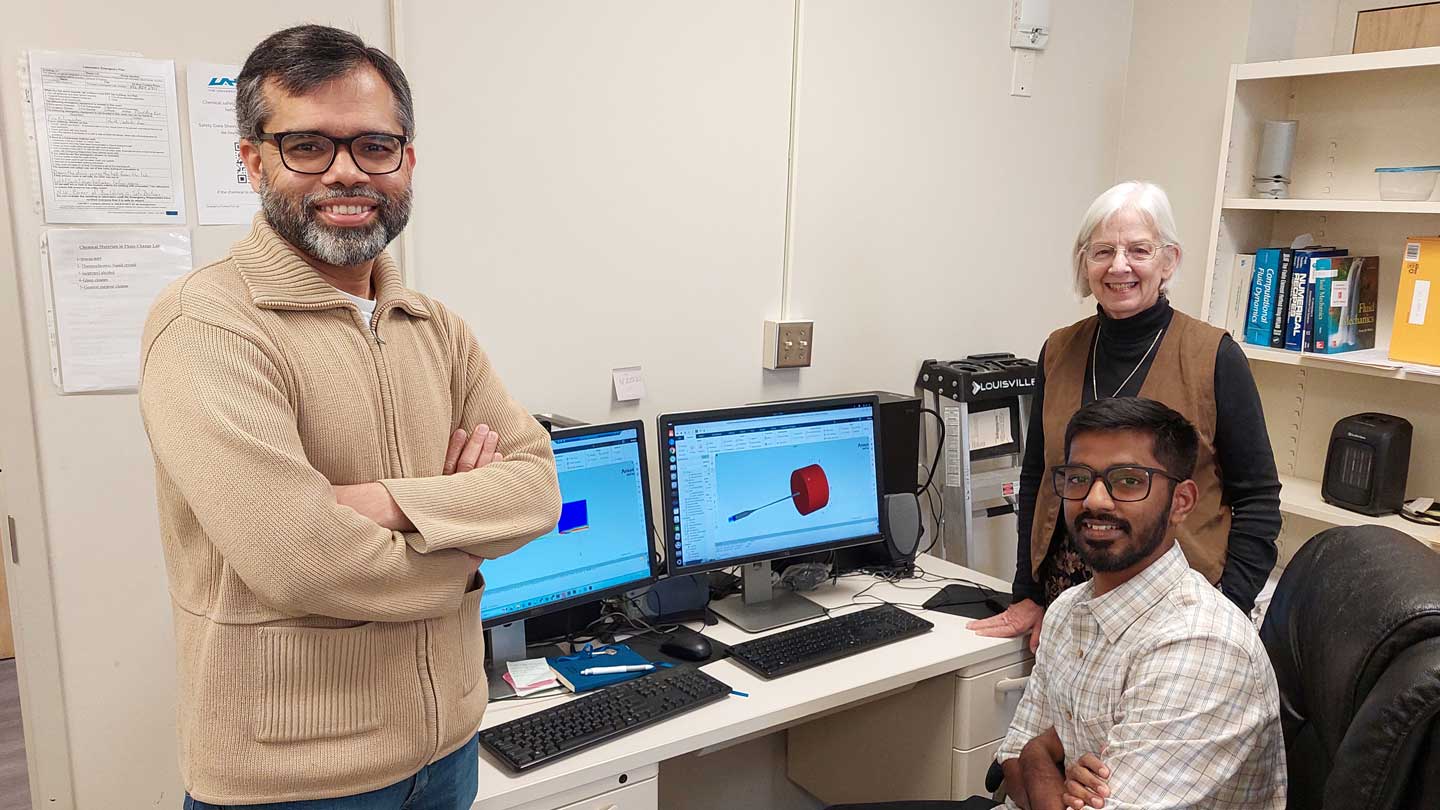

(Clockwise from left) Professors Sarma Rani and Judith Schneider, from the Department of Mechanical and Aerospace Engineering (MAE), and Aditya Iyer, a graduate student of Aerospace Engineering.

Two researchers in the College of Engineering at The University of Alabama in Huntsville (UAH) have received a grant from Titomic, Ltd., to develop a novel cold-spray gun that will use the flow of high-speed particles to repair damaged surfaces in engineering hardware without welding or the need of a blow torch. Professors Sarma Rani and Judith Schneider, from the Department of Mechanical and Aerospace Engineering (MAE) at UAH, a part of The University of Alabama System, are working to develop a computational model, as well as fabricate the advanced cold-spray gun, a project scheduled to run for one year.

“A cold-spray gun is cheaper and much safer to operate when compared to welding,” Rani explains. “Initially, Titomic was looking to improve the design of their commercially marketed cold-spray gun system. The project was envisaged as just a computational modeling effort to achieve the design objective. But, as our discussions with Titomic evolved and matured, they were interested in not just improved designs but also fabrication of actual spray guns based on the new designs.”

Cold-spray guns can play a pivotal role in the cost- and time-effective repair of structurally damaged parts in engineering hardware, particularly in aerospace applications. The system uses finely powdered, solid-state materials like metals, metal alloys and some ceramics or intermetallics to create coatings and build structures by driving the particles to high speeds.

The phrase “cold spray” refers to the absence of any external heating or combustion accompanying the spray process. Rather, solid metallic particles are sped up by the supersonic flow through a converging-diverging nozzle and are then sprayed onto the desired location. The speeding of particles is also accompanied by temperature increase so that when they impinge on the damaged surface, they are soft enough to adhere, forming a protective layer.

“At its core, the system consists of a converging-diverging nozzle for accelerating gas flow to high supersonic speeds (Mach numbers greater than 5),” the researcher says. “Converging-diverging nozzles (CD) are the large and most visible components of rocket engines.”

CD nozzles consist of a converging section that narrows to a “throat,” and then a diverging section that expands outwards. This unique shape converts thermal and potential energy into kinetic energy, with the flow becoming sonic at the throat and then accelerating to supersonic speeds in the diverging section.

Once the accelerated particles impact a surface, they deform to create a strong metallurgical bond without melting. This process uses the particles' kinetic energy for bonding, which disrupts the grain structure of both the particle and the substrate, causing them to form a strong, solid-state repair.

“Titomic is fundamentally interested in improving the design of their system to achieve optimal surface deposition of the particles,” Rani notes. “Since my expertise is primarily in computational investigation of high-speed, particle-laden flows, I approached my colleague, Professor Judith Schneider, to help with the fabrication. I and my graduate student Aditya Iyer perform the simulations and provide the necessary flow and particle data to Professor Schneider and her students, who will be designing and fabricating the cold spray gun. I’m also grateful to Professor Yu Lei of Chemical Engineering for his participation in the initial discussion with Titomic personnel.”

This year Titomic Limited opened its new manufacturing facility in Huntsville that will serve as the organization’s global headquarters supporting commercial and defense initiatives. The company specializes in manufacturing cold spray additive technology that supports oil and gas, defense, and aerospace industries.