Fused filament fabrication (FFF) is one of the most common and widely used additive manufacturing processes and is renowned for its simplicity, relatively predictable behavior, low cost, and wide variety of usable materials. The basic process works by extruding a molten filament from a nozzle and selectively depositing the material to build a solid part in layers.

ISEEM professor Dr. Sherri Messimer, along with former clinical instructor Albert Patterson, is augmenting grant funding with existing ISEEM lab equipment and facilities to conduct one of the largest material characterization studies of two of the materials used in FFF: acrylonitrile butadiene styrene and polylactic acid plastics. They'll conduct dynamic-destructive testing on over 100 thin-wall cylinders.

Typically used for rapid prototyping, FFF technology has many application potentials in healthcare, aerospace, defense, and more.

"The big thing in additive manufacturing right now is qualification and characterization of the materials. No one wants to talk about putting these parts in an automobile, airplane, a missile, or a person until we understand the material characteristics," says Dr. Messimer.

Since the cylinder construction is layered, the parts are more susceptible to fatigue because of the heat shock during the process. "The parts go through a lot of heat cycling," says Patterson. "Unlike inject- ion molding where you pull it out, it cools, and then you use it, 3-D printed parts are repeatedly heated and cooled, which can be really good or really bad for the properties. So we’re adding a factor in our experiment to fill them up with expandable foam in order to provide a cheap but good quality internal structure. It also adds some spring inside to absorb vibrations and make the part more durable.”

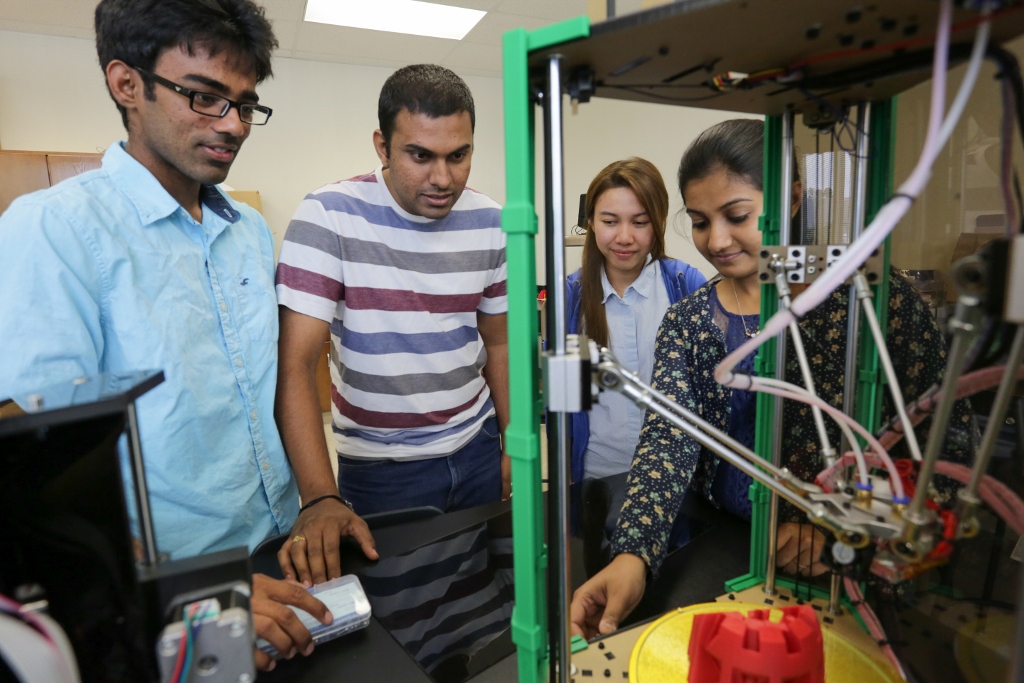

Under Patterson's guidance, students in the AM-associated CAD/CAM class are designing the testing device. "We’re actually additively manufacturing some of the parts right here instead of ordering them. Albert has managed to integrate these classes," says Dr. Messimer.

The ISEEM Manufacturing & Robotics Lab equipment includes Cube Pro, CTC Creator, and DaVinci Pro 3-D printers; material testing equipment; an environmental control chamber for testing environmental influence on material properties and for doing chemical treatments to parts; bath/soak facilities for chemical processing of HIPS and PVA materials; and a full set of post-processing tools.